We have moved to a new site!

So, more details about Samwash self-service car washes are available on the website

www.samwash.ua

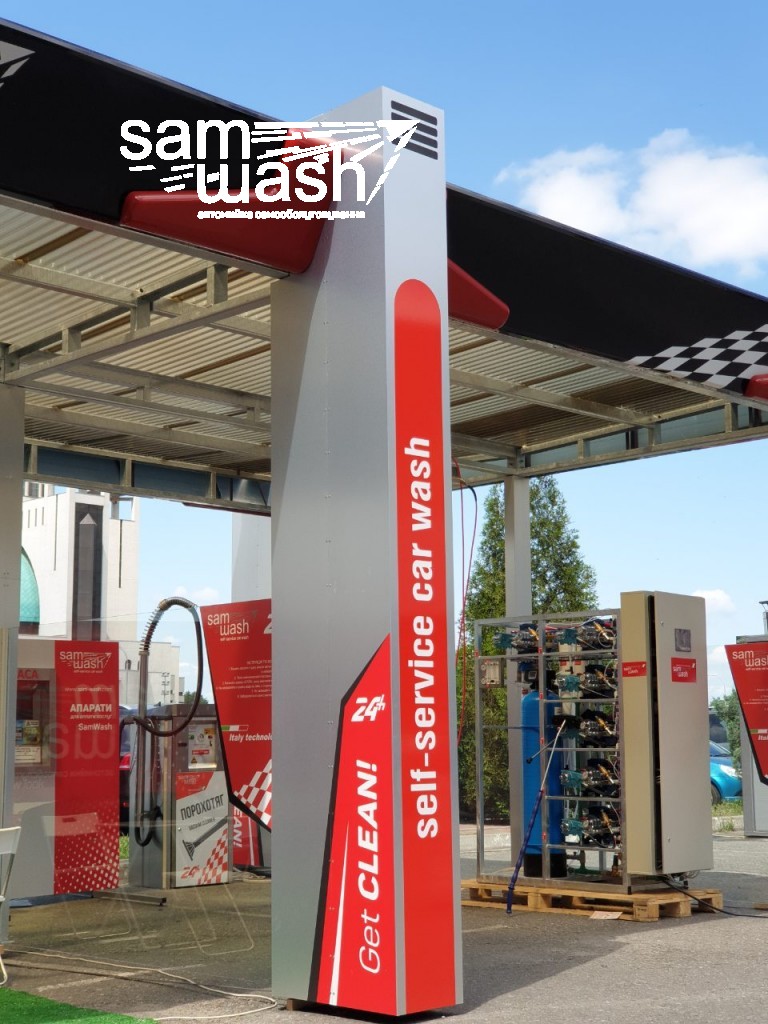

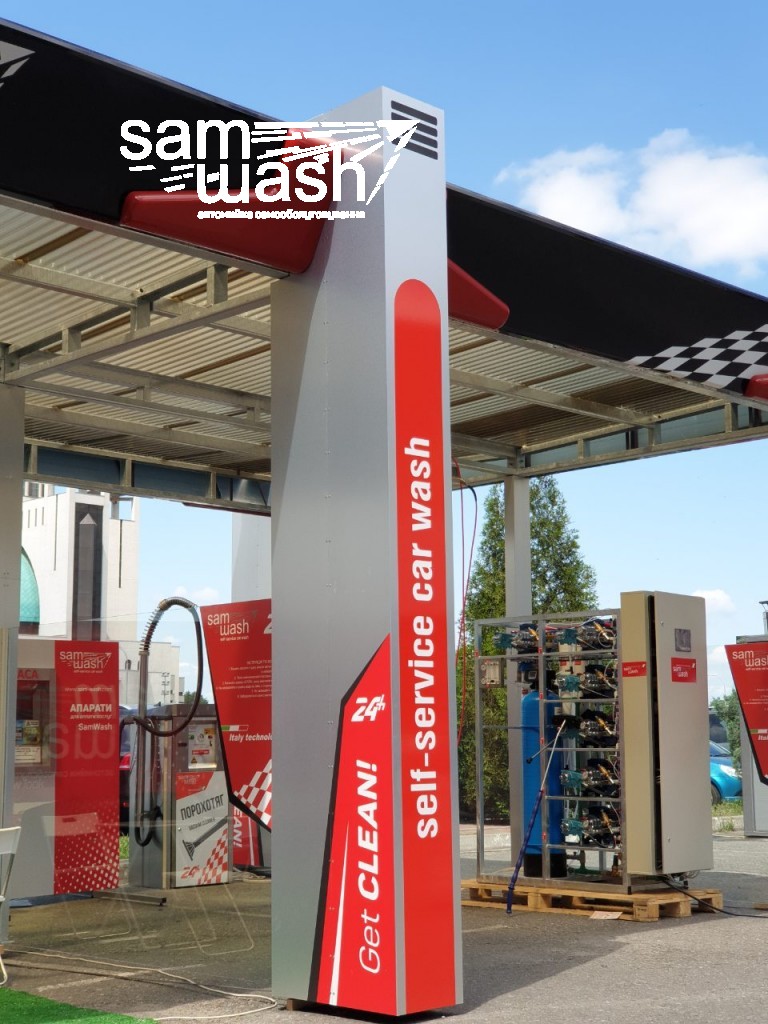

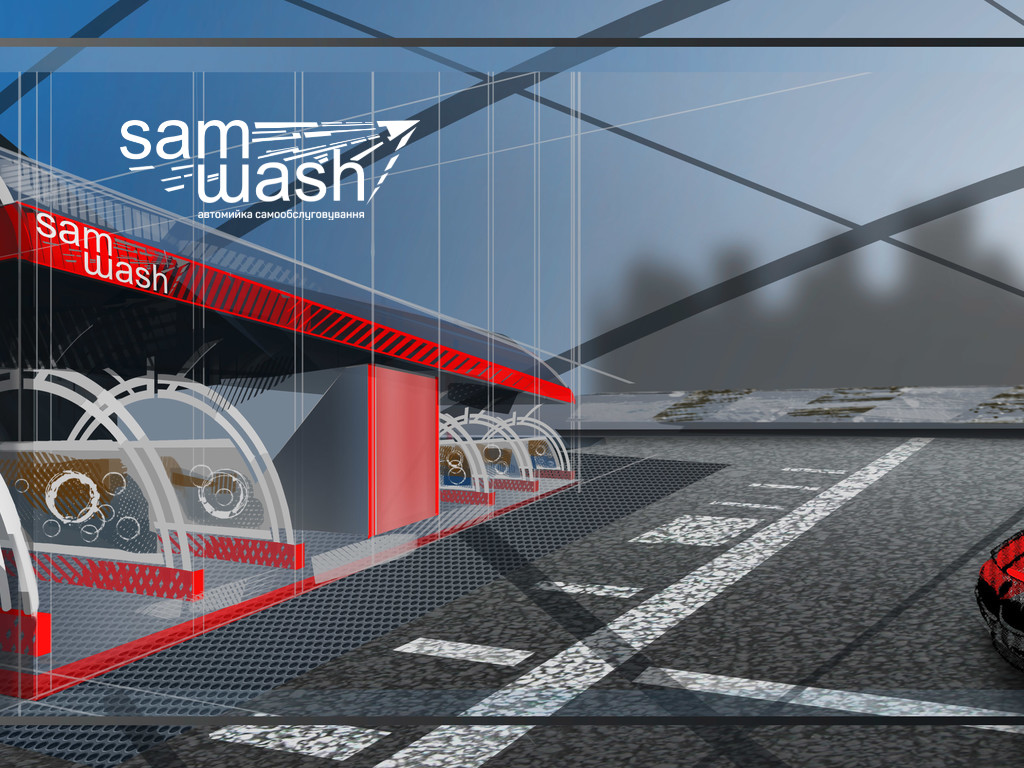

Equipment description

The process equipment is delivered on a metal frame and must be assembled at the manufacturer's factory. Standard size: 3000x800x2200 mm (height)

DOUBLE SOFTNER (with electroin control system)

Two-column water softening system containing 5 kg of quartz sand and 75 litres of ion exchange resins. The softener is fully automatic, it is started by a single head with a double control system that controls the production of softened water and the operating time of the softener. The water softening parameters are set based on the water analysis of the customer during the test procedures at the manufacturer's factory.

Rated output: 6000 l/year

REVERSE OSMOSIS SYSTEM

The reverse osmosis system consists of one, two and three columns with a diameter of 4 inches, which contain 2 osmotic membranes such as HIGH POWER. The system is connected to a PC and contains a built-in water meter that enables you to manage and control the production of osmosis and concentrate. The PC makes it possible to diagnose and control the reverse osmosis system. The novelty of SAMWASH is the use of car washes in both osmosis and concentrate, which saves up to 30% of water consumption.

Rated output: 300-900 l/year

CHEMICAL DOSAGE SYSTEM

Accurate dosing of chemicals is very important, as this affects the quality and degree of car washing at all car wash platforms. Electronic controlled metering pumps supplied with the equipment guarantee the ideal consumption of chemicals in accordance with the percentage specified in the specifications for these chemicals.

The pump for each chemical has an electronic water volume counter that regulates the operation of the pump in accordance with the volume of water required for each washing platform. Electrical chemical dispensers allow you to dose chemicals from 0.1% to 10%.

WATER LEVEL HOLD-UP SYSTEM

After using water, the water is restored independently in the tank. The accumulation tank with the pump drives water through the anti-frost system. Using two indicators, the water level is checked, so the tank is always full.

HYDRAULIC CIRCULATION

To work with concentrate and aggressive chemicals, all pipes and manifolds are made of plastic, connected thermally and have brass or stainless couplings.

ELECTRONIC CAR WASH SYSTEM

The entire electrical system is made of high quality materials and components in accordance with EU standards for safety, efficiency and reliability. The control panel contains a PC and a magnetic thermal differential fuse switch that provide excellent protection against short circuits and direct or indirect contacts, which is also useful for sectional cycle interruption. The dialogue interface of the PC allows you to monitor, store and control hours of operation, intervals between service sessions, warnings and signals, settings of credit terminals, cash income etc. The remote control system with the help of Ethernet connection through the telephone line allows for remote technical check and maintenance, responds to warnings and signals, and receives alarm messages.

HIGH PRESSURE WASHING SYSTEM

Each washing platform is operated by a high-pressure module consisting of a pump with a pressure of 150 bar — 11 l/min; 6-pole induction motor, 950 rpm; connection of an electric motor with conical flanges and damping assemblies. The pump is supplied with a nickel-plated head and a special plug for high-pressure water, suitable for operation at temperatures up to 80 C. The pump supply is controlled by a system with 4 electromagnetic diaphragm valves, which selects the type of water in accordance with the washing programmes. Each valve is protected by a filter and has a spherical cover that allows maintenance. In accordance with EU standards, the washing system has factory settings for maximum operation at 90-120 bar —11 l/min and 45 C.

AUTOMATIC ANTI-ICING SYSTEM (anti-frost)

The system is equipped with an external temperature sensor connected to the anti-icing system, which switches on at a temperature of 2-3°C (factory setting). Starting of the anti-icing system leads to water circulation all the way to the nozzles at each washing platform. The anti-icing system does not interfere with the car wash system and does not affect its normal operation. This system has three levels of protection and appropriately protects car wash equipment during work at low temperatures and extreme conditions.

| Designation | Mini | Mini+ | Standart | Standart+ |

| Galvanized metal frame for equipment fixing | + | + | ||

| Stainless carrier metal frame for equipment fixing | + | + | ||

| Single-column mechanical water softener Rated output: 1400 l/year |

+ | + | ||

| Double electronic water softener 2x75 (manufactured by FLECK) Rated output: 6000 l/year |

+ | + | ||

| Double electronic water softener 2x75 (manufactured by FLECK) Rated output: 6000 l/year |

+ | |||

| Single-column simplex osmotic membrane of HIGH POWER type in stainless or ceramic housing Rated output: 125 l/year |

+ | |||

| (manufacturer — FILMTECH) 1,2,3 osmotic membranes of HIGH POWER type in stainless or ceramic housing Rated output: up to 900 l/year |

+ | + | ||

| Inlet water purification filter | + | + | ||

| Coal filter | + | + | ||

| Submersible pumps (osmotic water, concentrate and anti-frost) or centrifugal pumps (depending on the technological part of the project) (manufactured by ESPA or LOVARO) |

+ | + | + | + |

| Electronic pump systems for chemicals dosing (manufactured by ETATRON) | + | + | + | + |

| High pressure washing system Pumps with electric motors 2.2 kW 150 bar (manufactured by INTERPUMP or ANNOVIREVERBERI) |

+ | + | ||

| High pressure washing system Pumps with electric motors 150 bar with Schneider inverters 2.2 kW. (manufactured by INTERPUMP or ANNOVIREVERBERI) |

+ | + | ||

| High-pressure-washing-system2 | + | + | ||

| Anti-frost system with water circulation system. | + | + | + | |

| Car wash control system (manufactured by Schneider) | + | + | + | + |

| Car wash control system with TOUCH SCREEN system (manufactured by Schneider) | + | + | ||

| Solenoid valves and connecting fittings are manufactured in the EU and US as a set | + | + | + | + |

| High pressure hoses as a set | + | + | + | + |

| Low pressure hoses as a set | + | + | + | + |

| Car washing guns as a set | + | + | + | + |

| Guns-holders | + | + | + | + |

| Tokens receiving box | + | + | + | + |

| Pantographs with damper | + | + | ||

| Pantographs with double dampers | + | + | ||

| Ergonomic brushes | + | + | ||

| System of clearing transactions, NEXT KEY and EURO KEY | + | |||

| Remote access | + | |||

| Token exchange machine | + | + | + | |

| Tokens for exchange 3000 pcs. | + | |||

| Gas boiler with heater and fuel framework as a set | + |

Consumption indicator for 1 platform

- of electric power 2.5 kW

- - of water 11 l/min

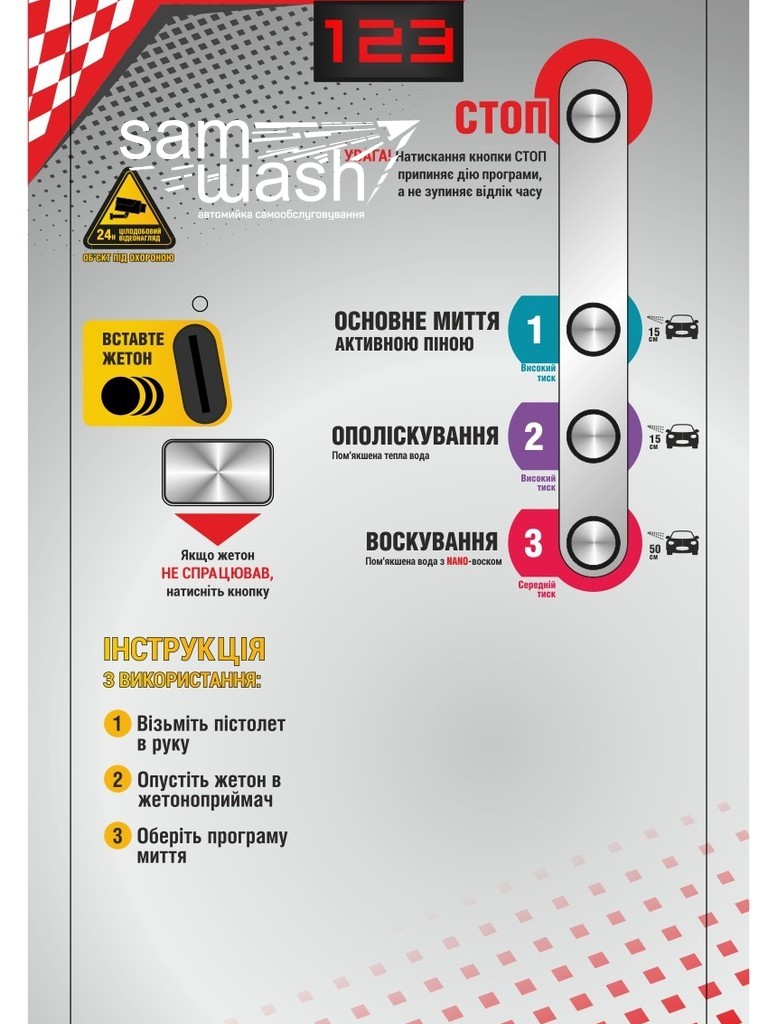

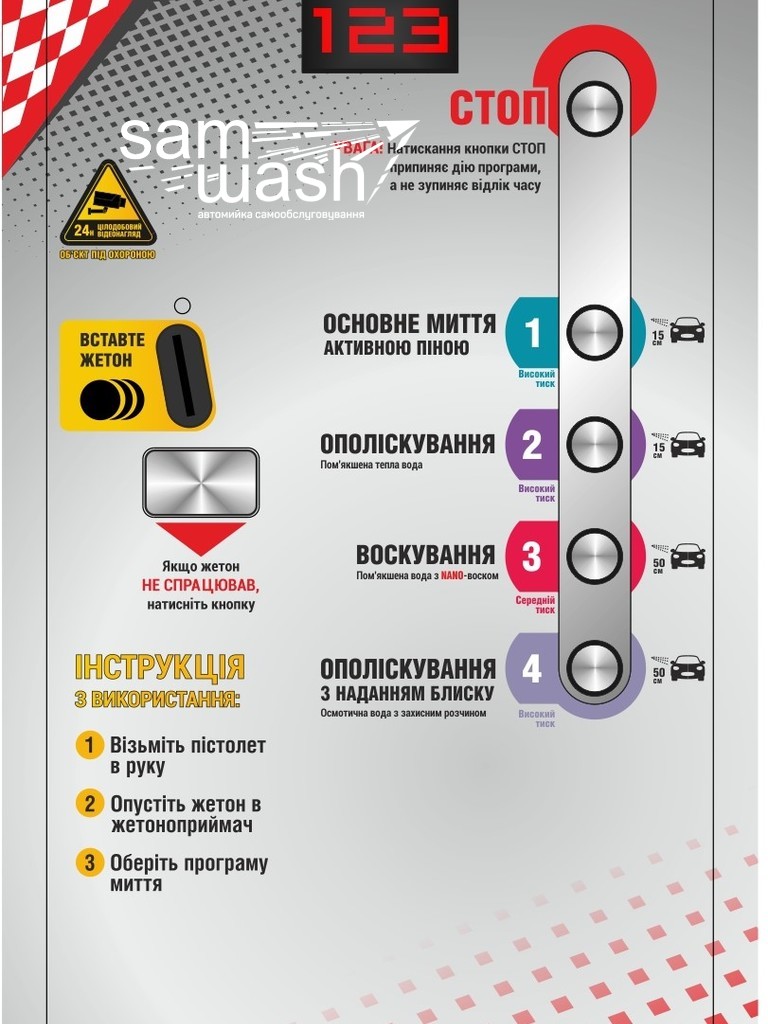

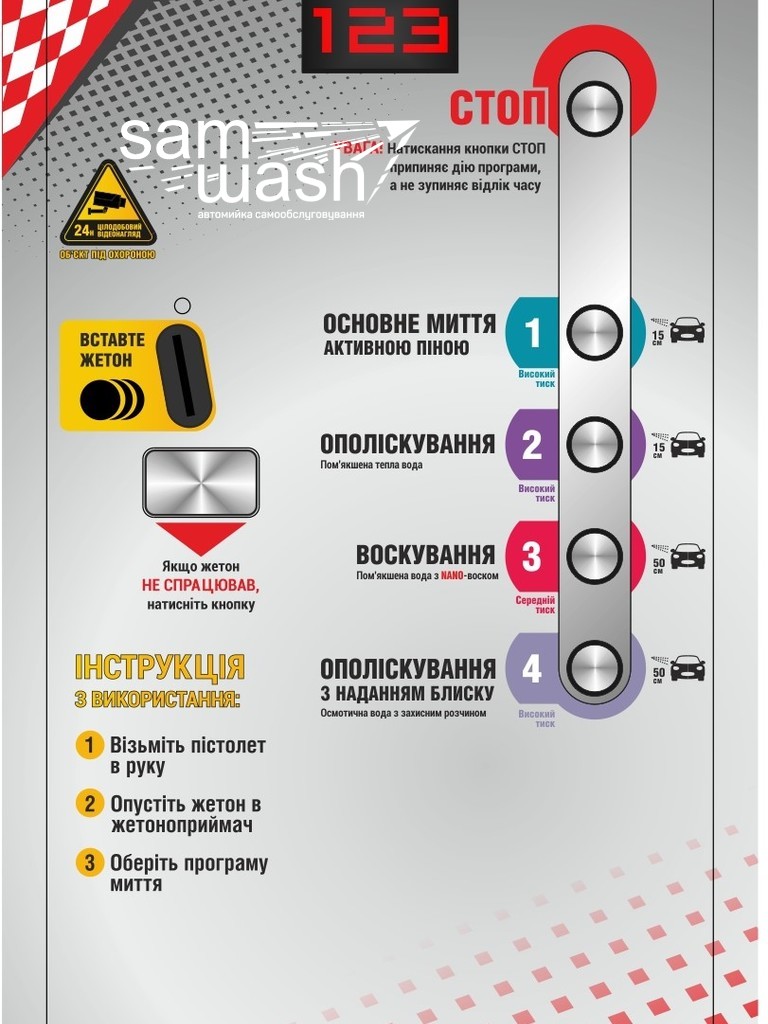

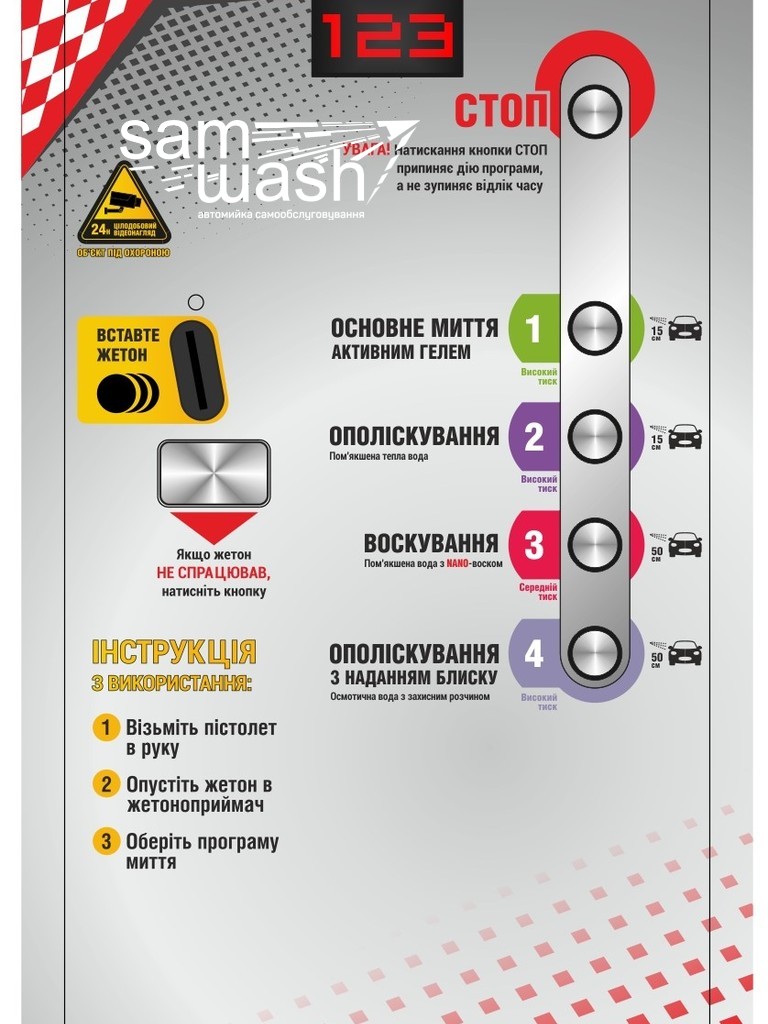

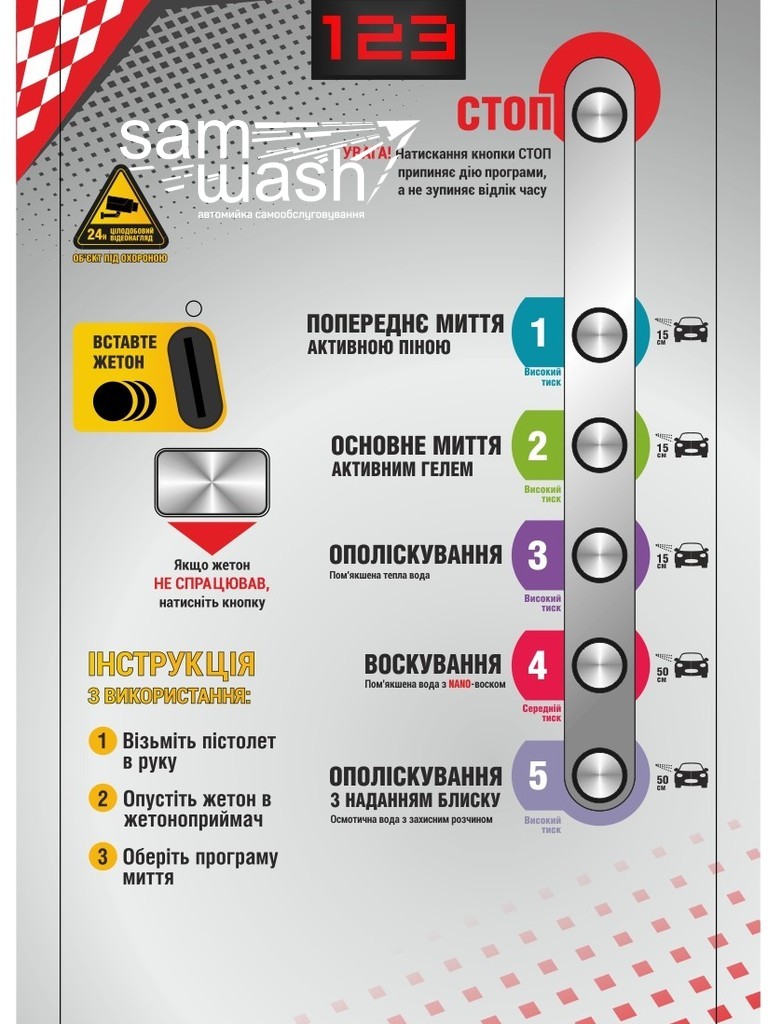

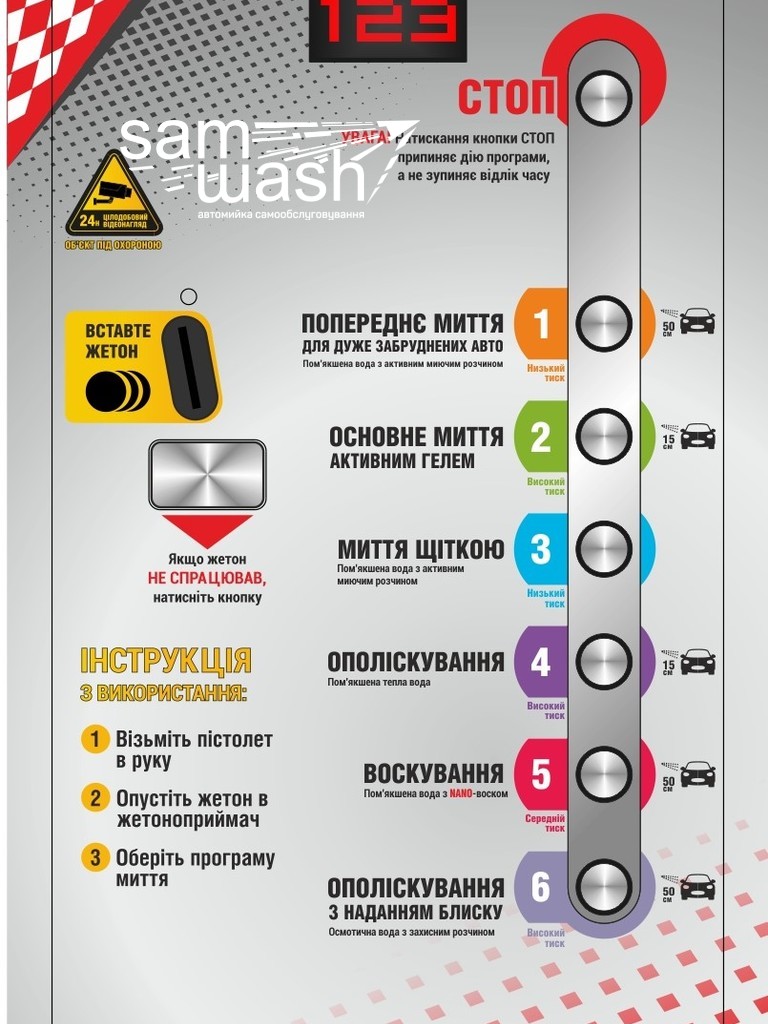

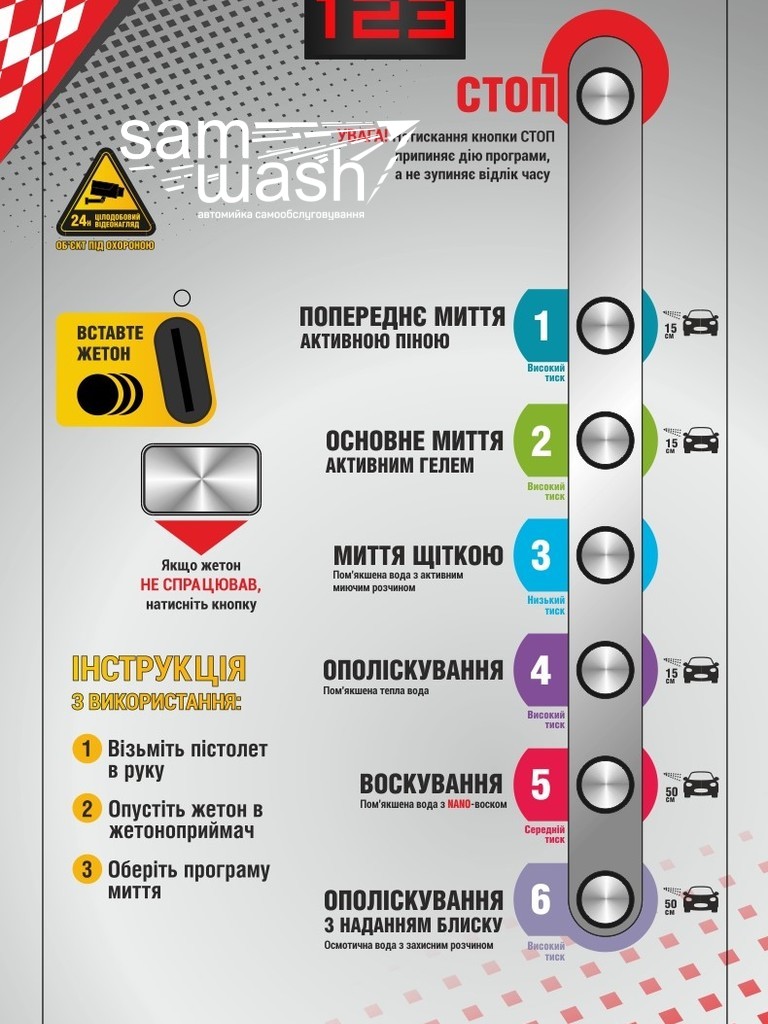

We offer the following washing programmes:

Programme No. 1 — Preliminary washing for heavily fouled cars

Programme No. 1.1 — Active foam

Programme No. 2 — Main washing with gel.

Programme No. 2.1 Washing with a brush.*

Programme No. 3 — Rinsing.

Programme No. 3 — Waxing.

Programme No. 5 — Rinsing with brightening.

*we recommend to use washing with a brush programme at open end platforms.

COMPONENTS

All components of SAMWASH equipment are manufactured in the EU and USA

MOUNTING WORKS

Installation work is carried out by Italian and Ukrainian engineers jointly. Installation works are included in the cost of the equipment.

Product catalog

NEWS AND PUBLICATIONS

SAMWASH TERMS

Apr 23, 2019

SAMWASH GUARANTEES THE EXPENDITURES AT 15.85% IN THE YEAR OF THE YEAR WRITTEN WITH WARRANTY IN 24 MONTHS.

More about the control panel for the car wash

Apr 17, 2019

The control panel and program selection is specifically designed and patented by SAMWASH, taking into account the climatic characteristics and customer preferences.

The combination of new computer-based developments, electronics, touch panel and design makes this control panel truly superb.

Despite all its technical strengths, it has been working reliably for many years and is designed to handle more than 12,000,000 pressures.

- New

- Popular

- Download

SAMWASH Company presented Ukraine with a decent presentation at an international exhibition in the city of Varshava

WRITE US

CONTACTS

Lviv, 79018

street Kulparkovskaya 108